I have been using candle wax (parrifin) to flux my leadpot but just recently I have been seeing alot of people using sawdust. My question is …

Is there any advantage to fluxing with sawdust over candle wax ?? Both seem to catch on fire ??

https://www.sixguns.com/crew/simplefluxing.htm

What one of the oldtimers, Glen Fryxell, had to say.

Tends to definitely side with the sawdust theory .

I always do my casting out doors with the wind blowing the fumes away from me.

I use beeswax. I get it in bulk for a muzzleloading lube that I make and the little bits needed to flux don’t consume much. I read somewhere that it also reduces corrosion of the steel components in the pot (I use a bottom pour)

He seemed to study the science behind it as well as having the experience

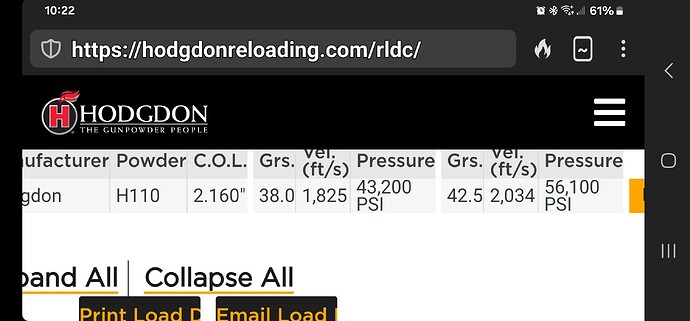

I use a harder cast lead ,I water quench which has been proven to improve hardeness 2-4bhn. I load for the 460 and are pretty hot loads and i am thinking I am in the 43000-55000 and went from 38.0gr. Up to 40.0 . Scared to do 42.5 since 40.0 was all I even wanted . I was like shazaam ![]()

![]()

I always said experience is the greatest teacher.

I am getting obturation due to the levels I am running at. But that article is so true very true

He wasn’t considering the 460 or the 454! BH on those need to be near copper alloys.

He has another article on gas checks, “variations on a near perfect theme” Good read.

Yeah, I gas check my rounds. Would love to read that also . I did read ever word. Great stuff.

I dont have a tester but there is an older you-tuber named fortunecookie45 and I did the fingernail test like he showed and mine don’t mark up

When you have time to read all of Fryxell’s work google “The cast bullet articles of Glen E Fryxell”

Variations on a Near Perfect Theme is on page 250+/- of 300 or so.Go to the one LASC.US…

@albroswift have you ever watched the you-tuber I was mentioning? He is a revolver lover and reloader. I been reloading a long time but only casting about 2 yrs.

On my list but don’t watch enough YouTube. Ill get to it!

Camping this week. Elmer Keith Shoot next week.

My wife hates my you tube list its all engine transmissions and guns and reloading ![]()

Man oh Man I wished I was camping alas just a couple days off and back to the job. I had church this morning so one day off on either side of Sunday doesnt make for mich enjoyment . Couldnt really turn down the current job Im on as it is literally double my normal salary. Working myself to death I suppose

I retired at age 62 two years ago. Don’t know where I ever found the time to work. So much to do around here . . . and it’s all mostly fun and definately low stress. Ahhhhh.

Loaded some more hunting rounds for deer hunting , one thing that amazes me every time I go to the reloading table even with 6 months between visits . I gind that it all comes back to me like riding a bicycle each step inthe process.

- Cleaning( which the tumbler does that for me

- Primer holes cleanout and inspection.

- Trimming ,chamferring,deburring

- Belling of case mouth

- Pressing in primers

- Weighing of my powder charges one at a time.

- Filling the caes one at a time.

- Setting the bullets in the case mouth

- Pressing/Seating in the bullet till the case is near to the top of the crimp groove.

- Crimping the case.

The finished product is always satisfying at the end.

I am down to about 30 cast bullets left so soon I will have to make some more.

I just ordered 15 more pounds of lead. Which I have figured out that at 300gr.(which they drop at about 295 minus the gascheck)

I get about 105-110 bullets from a 5 pound bar of lead.

Mathematics says 5 pounds of lead should yeild me 116 bullets at 300 gr…lol …don’t ask me where those few unrealized bullets disappear too… my guess is from the sprues ,which I try andntoss back in and I have learned from many videos on-line that most leave a little lead at the bottom of the pot. So between those 2, I suspect i loose those 5-10 bullets ![]()

Anyone else run short.

7000 grains per pound of lead divided by your grain of bullet/bullet mold.